-

Companies like Copreci, with production plants in Europe, Asia, Africa and America are very attractive for young students of the Master in Internationalization of Mondragon Unibersitatea.

Copreci collaborates since the first edition with MU in this Master oriented to allow participants to experience in first person the internationalization and cultural adaptation of companies. We live in a globalized world and companies are no strangers to this scenario. For this they need agile professionals who can manage with judgment, speed and efficiency in these highly competitive and changing global environments.

Yesterday we had the eighth collaboration of Copreci with MU, we hope there will be many more. Copreci, partner that collaborates with universities.

-

Last October 16th, took place the 6th edition of the Electrolux Supplier Awards at the headquarters of the Electrolux Group in Stockholm.

The Group has more than 3,000 suppliers and about thirty of them were chosen for the event in different categories. In the Innovation category, Copreci was finalist along with two others, which is a great recognition of the work developed by the cooperative in this area.

The event was attended by the highest representation, with the presence of Jonas Samuelson, President and CEO of the Electrolux Group.

From left to right, Josu Zaldua, Copreci Gas Cooking EMEA Director, Milena Nanni, Commodity Manager of Electrolux, Fernando Muñoz, Sales Manager of Copreci and Filippo Milanese, Vice President of Purchasing Europe of Electrolux. -

Copreci introduces its new High BTU gas valve with CSA certification. This LOG 22700 series valve is especific for high flow thanks to its 140,00 BTU/h NG 20 mbar. It has safety and it is valid for both gases LPG/NG. A very suitable valve for gas logs, firepits..

See pdf

-

Here it´s our corporative video in korean.

-

Copreci opens the Innovadores section that the El Mundo newspaper dedicates to the innovation world

More info at: INnovadores

-

COPRECI in collaboration with FAGOR Industrial and Ikerlan will develop the project "Innovative Applications of High Efficiency in the Industrial Cooking".

This project, called "INHECOOK", will get financial aid from the Ministry of Economy and Competitiveness under the "RETOS" program for the period 2015-2017.

-

This new system makes the hood work autonomously, without user interaction, thus avoiding touching the hood controls. When the cooktop is switched ON, the hood is also automatically on, starts working.

And the extraction power adapts automatically to the flame level, if the gas power decreases, the extraction power will follow.

Relax and forget the controls of the hood, Clean Hood will do it for you.

-

The new ECOpack packaging developed by Copreci for its induction hobs, saves in every way. It is a reusable packing system, since the customer may reuse it as end packaging once the assembly and adjustment of the glass top has been made. This avoids duplication of packaging costs, with consequent benefits for the environment and a simplification in the supply chain and inventory control.

Copreci also delivers its induction modules to customers ready for installation in the final application, tested and guaranteed to meet the EMC standards (Electromagnetic Compatibility), which greatly simplifies the process and reduces the "time-to-market."

Morever its new slider interfaces (mono and multi-slider) allows a convenient control and precise cooking.

-

Copreci´s production plant in the Czech Republic has obtained an endowment of a European Social Fund to implement a training plan among its workers of its BLP3 drain pump unit. The project is provided with CZK 1.085.160,75CZK, the start date of the program is November 1, 2013 and it will end on November 30, 2014.

In the project, whose name is “CZ.1.04/1.1.04/B3.00102 /Support Area: 4.1.1 / Axis : 4.1 Adaptability”, will take part 43 workers and is funded by the FEE resources through the Operational Program "Human Resources Development"(OPHRD) and the budget of the Czech Republic.

The objective of this project is to increase the professional skills of the current and new workers and train them to work in the new BLP3, dedicated to innovative drain pumps for washing. This is a single line in the Czech Republic.

-

With this certificate, Copreci declares its commitments related to Corporate Social Responsibility.

Corporate Social Responsibility is part of the very essence of Copreci, which guides its activity to the development of people (betting on their trainning, participation and transparency in the information), creation of a safe and high quality work environment, creation of preferably cooperative employment, interoperable solidarity, and sustainable development. In addition to this SR10 Social Responsibility certification, Copreci has the OHSAS 18001 certification in Occupational Health and Safety, ISO14001 Environment and ISO9001 Quality.

More info -

Copreci has developed the heart of the electronic system of this induction hob with a temperature sensor and core temperature probe. This project opens a new range of solutions to cook with precise temperature, allowing to control cooking time and temperature. With low-temperature cooking you will prevent food from losing nutrients, ensuring that its nutritional values are better preserved.

The Rocook project has been developed by CATA appliances, the company Lékué and Alícia Foundation for the prestigious restaurant El Celler de Can Roca. For this they have had a multidisciplinary team in which have participated Copreci, Eika, Mondragon University and the Engineerings Zermik and Perspectiva. Thanks to a temperature sensor and a core temperature probe we get the optimal flavor and texture in each recipe. Rocook Induction allows you to cook with precise temperature control or by power setting (like a traditional induction cooker). Its light weight and small size allow it to be stored in any kitchen cupboard, and you can even transport it inside a travel case. It is very easy to use: all you have to do is programme the temperature you want to cook at and the cooking time.How does it work?: see video

Where to get your Rocook -

A few months ago Copreci started at its plant in Zhuhai the manufacturing of components for washing appliances, exclusively for the Asian market. This catalog is a milestone in positioning Copreci in the asian washing sector.

-

Copreci´s production plant in the Czech Republic has obtained an endowment of a European Social Fund to implement a training plan among its workers. The project, to be completed in May 2015, is provided with CZK 2,117,909.43.

In the project, whose name is “CZ.1.04/1.1.02/94.00635/Support Area : 4.1.1 / Axis : 4.1 Adaptability”, will take part 28 workers and is funded by the FEE resources through the Operational Programme "Human Resources Development"(OPHRD) and the budget of the Czech Republic.The main objectives are:

- Increase the effectiveness of business processes and increase the competitiveness of the company in key areas.

- Promote knowledge and skills.

- Improving communication between management and middle management.

-

The article describes the alliance between the cooperative and the company Tarpuq, located in Cuenca (Ecuador), for the manufacture of induction modules, which are then sold to local manufacturers of appliances such as Indurama, Mabe or Fibroacero.

-

The Harmony Project, whose name stands for "Holistic Approach to enhance the Recyclability of rare-earth permanent Magnets Obtained from aNY waste stream," contributes to the EU Circular Economy Action Plan (2020).

This project emerges in response to the urgent need of the European Union to become independent from China's dependency on the supply of rare earth elements (REE). This dependency has been identified as a critical factor in ensuring crucial value chains for the European economy.

By joining the Harmony Project, COPRECI commits to significantly contribute to the development of innovative solutions that enable the recovery and efficient recycling of rare earth magnets from various waste streams. This collaboration strengthens COPRECI's commitment to promoting sustainability and the circular economy in the region.

More info at: htttps://www.harmonyproject.eu/the-project/ -

Copreci debuts a new language on its website. The plant located in the turkish town of Gebze, has promoted the implementation of the site in this language. " We want to meet customers needs in this geographic area, providing technical information in their own language, which is highly valued."

More information: Website in turkish

-

During the first half of 2018, Copreci de México remodeled and expanded its facilities in its plant in Guadalajara. Copreci de Mexico was created in 1989, being the first production plant of Mondragón Corporation abroad. Now, Copreci de México has a modern and efficient facility, which ensures the future commitment of this plant.

-

In Copreci we have many runners and this Sunday they showed off in the Mundukide Fundazioa Solidarity Run, which is now in its eighth edition.

It is always a pleasure to participate in a solidarity event like this, surrounded by nature, companions and friends. The money raised through the event will be invested in Mundukide's cooperation programs in Africa and South America. #EmanPausoa

-

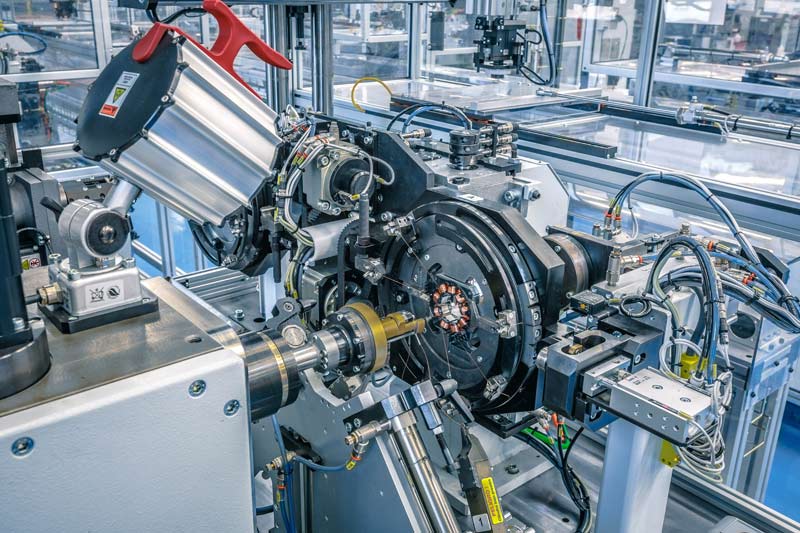

Copreci has developed a new BLDC circulation pump for dishwasher, a further step in the extension of the product portfolio for pump&motor applications. This development positions Copreci as a benchmark in the use of brushless technology in wet rotor chamber motors. Also enables new developments, both in higher power requirement applications, as in other sectors such as ventilation.

Copreci has developed this new product together with the world's leading dishwasher manufacturer. Meets the highest standards of energy efficiency, water consumption and the lowest noise level in the market.

The flexibility of the product allows offering customized solutions that meet the individual and specific requirements of the customers. From the integration of the heating function, with either tubular type elements or Thick Film heaters, to the inclusion of the electronic control, covering a wide range of domestic and industrial applications

The BG9 can be manufactured both in Aretxabaleta and in Czech Republic factories, depending on the customer’s needs.

The new production line incorporates a modern traceability control as well as the latest manufacturing technologies such as needle winding and magnetic transfer systems.

-

The new series of Wanagement - Water management- products has a common feature: energy efficiency with reduced consumption of electricity, as well as significant noise reduction.

It is an autonomous drain pump with embedded electronics, that dramatically reduces development time and does not require a large investment in the washing machine control, being easily integrated into any type of washing machines. It also has Smart Draining, a constant flow regardless of the height of the washing machine drain and the elimination of the "snorkel" effect.

This is the first time that the BLDC technology is incorporated in washing machines - so far only had been used in dishwashers, and offers great reliability and excellent results in the washing cycles.

-

Consumer Reports is a renowned American independent magazine, which has been serving consumers since 1936 through their rating, fair assessment and thorough investigation of goods.

In their latest April 2015 edition, the BOSCH Ascenta dishwasher (SHX3AR model) has been awarded as the CR Best Buy for American consumers owing to its good value for money and a washing-cycle /water- use ratio of 90 min/6 gal. A model ranked as well as one of the quietest and especially efficient, features to which Copreci contributes with their BLP3 pumps, distinguished because of their low noise level and a really efficient use of water and energy.

In the same way, 10 out of the 12 best qualified dishwashers use Copreci drain pumps.

-

'Lantegixa herri' is the title of the song, created to celebrate the 50th anniversary and performed by company employees. The video was taken in Aretxabaleta production plant and in various locations in the town of Aretxabaleta.

Almost twenty workers of Copreci have been involved in the recording of the song and video 'Lantegixa herri', a song created for the purpose of 'commemorate 50 years of the cooperative and pay tribute to the founders'.

The theme of the video is "the heart present in millions of appliances, in millions of homes around the world, but mostly present in all men and women who make up the cooperative."

-

New heater sizes, with more power are the main new features of the Ecook series. A unified and consolidated platform, 100% reliable with long experience in the market, which distinguishes itself by offering customers a ready to connect product after certifications and approvals , which simplifies its market launch.

The Ecook series incorporates a special feature that allows the user a more efficient management of energy. This function manages the power consumption of the hob and warns the user, by an acoustic signal, when the limit set is exceeded.

Copreci also integrates a new wireless communication system between the hob and hood, called CleanHood. The hood needs no supervision, it works autonomously, so the cooker hood´s reamain clean as they are rarely touched by greasy fingers… Moreover, Ecook series it´s known for its flexibility and adaptability, it can be easily integrated in any final application built -in , free - standing or polyvalent and different sizes in both widths, and depths.

Copreci has more than 20 years, developing different generations of induction with the aim of providing an assembled and certified solution, ready to integrate into the final application.

More info: 2014 catalogue

-

Coneglianon kokatutako plantako produkzio fluxua eta layouta hobetuko dituzten instalazio berriak

New facilities that improve the productive flow and layout of the plant in the town of Conegliano.

In 2002, Copreci acquired a company producing tubular components for gas cookers and hobs in Mareno di Piave, 60 km from Venice, with an area of 3800 m2 spread over 3 pavilions.15 years later it moves to a wider location, 5000 m2.

This expansion reinforces the commitment to growth and internalization of the cooperative, according to "lean production" that has been applied in all its plants.

Page 3 of 6